You will acquire basic knowledge about how to adjust a color as well as an overview of the different kinds of pigments and their specific characters.

MOVIE - COLOR ADJUSTMENT

INTRODUCTION

Even if your color search does not offer a satisfying solution and blend-in repair is not applicable, you can still adjust the color of a formulation.

The aim of color adjustment is to change the color to ultimately match the target color as exactly as possible. This color adjustment, also referred to as “color matching”, is achieved by adding mixing bases, which mainly contain a binder and the coloring pigment.

The sections below present a detailed overview of the color adjustment process (color matching with different tools).

If you want to use the color adjustment process with a spectrophotometer you can find the detailed information in the modules “COLOR RETRIEVAL WITH RATIO SCAN II” or “COLOR RETRIEVAL WITH RATIO SCAN 12/6”.

TOOLS FOR COLOR ADJUSTMENT

What kinds of tools are available to support the color adjustment?

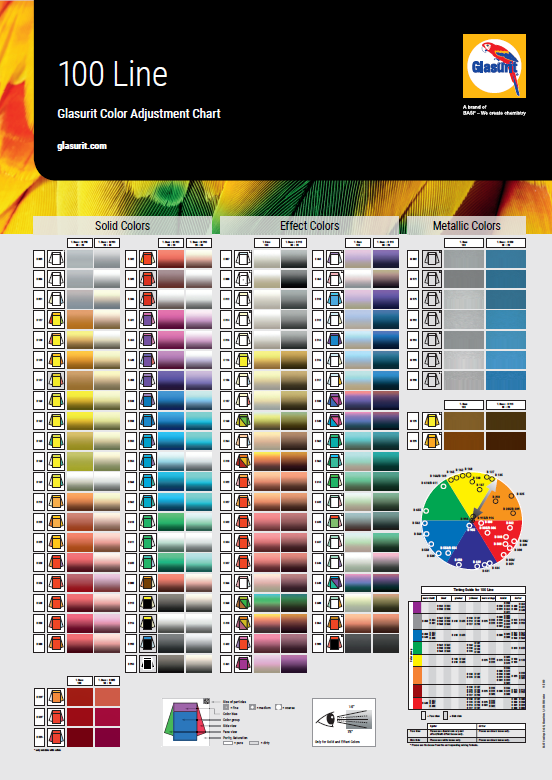

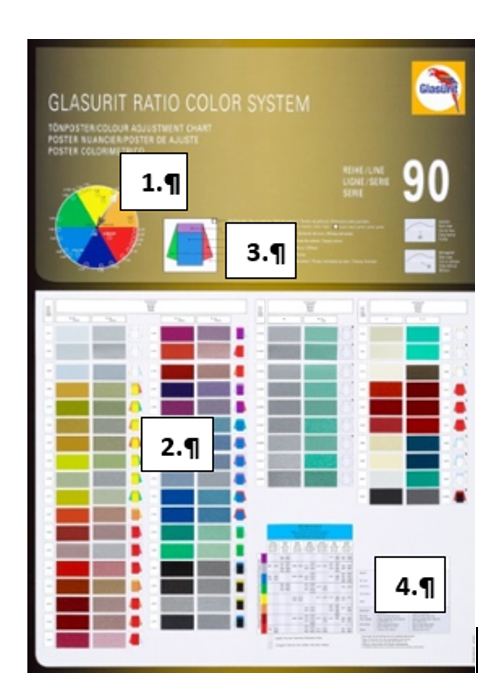

Color adjustment charts

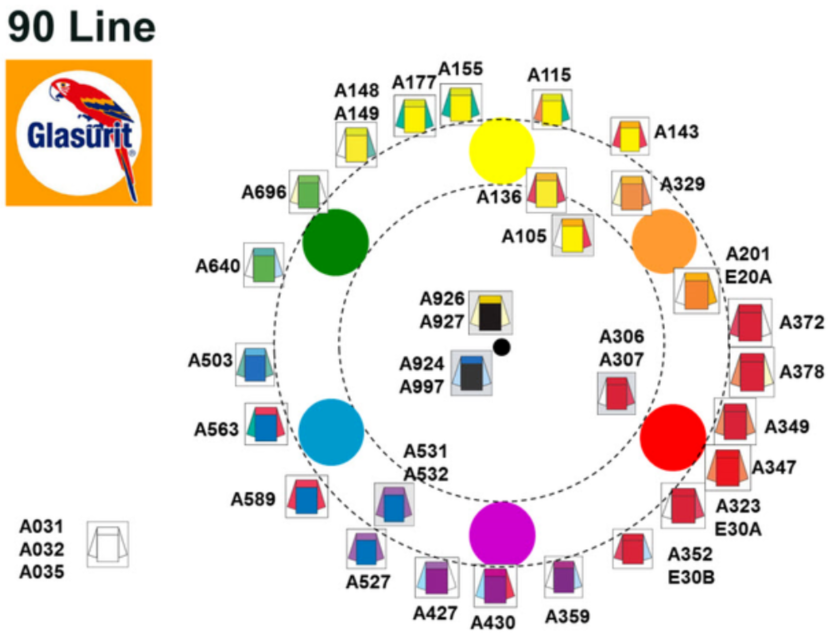

Color adjustment charts offer an overview of all mixing bases and provide information on color groups, color bias, face view and side view, as well as purity and chroma, making them a valuable aid to color adjustment.

COLOR ADJUSTMENT CHARTS

|

100 Line |

90 Line |

55 Line |

22 Line |

Multi - Effect |

ELEMENTS

POSITION OF THE MIXING BASES IN THE COLOR CIRCLE

Provides the position of the single mixing bases within the color circle. It provides orientation for the color of the single mixing bases and their relation to each other. In addition, the color and the purity of the mixing bases are indicated. Pure colors are located toward the outside of the circle, and less pure and dirtier mixing bases are located closer to the center of the circle. By placing the color to be adjusted in the circle, you will obtain a clear indication of the different mixing bases that impact the color.

Position of mixing bases

TINTED MIXING BASES (COLOR DIRECTION/COLOR STRENGTH)

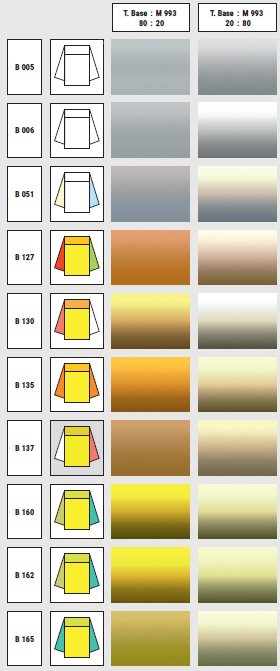

The chips provide the color of the individual solid mixing bases, these are reduced down using a silver mixing base. 80:20 & then 20:80 to show the tinting strength & color direction. Effect or Silver mixing bases are shown in their pure form & also reduced down with a solid color tinting base.

Tinted mixing bases

TINTING CHARACTERISTICS OF THE MIXING BASES

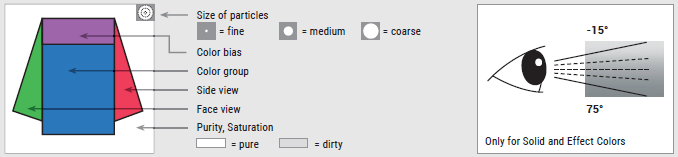

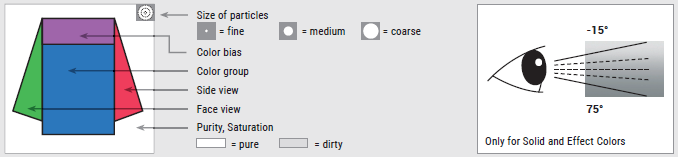

What is the effect of the mixing base on the color? All major aspects of the single mixing base are presented in the figure beside.

Pictogram of the color adjustment chart with description

Explanation of the example: The image shows a blue color (color group) with a tendency toward violet (color bias). The face view shows a tendency toward green, while the side view (flip) shows a tendency toward red. The background color would be either white or grey. White depicts it is a clean or pure tinter, grey background depicts it is a dirty or has a low saturation.

Here you will find further information regarding the viewing angle: BASIC KNOWLEDGE COLOR: VIEWING ANGLE

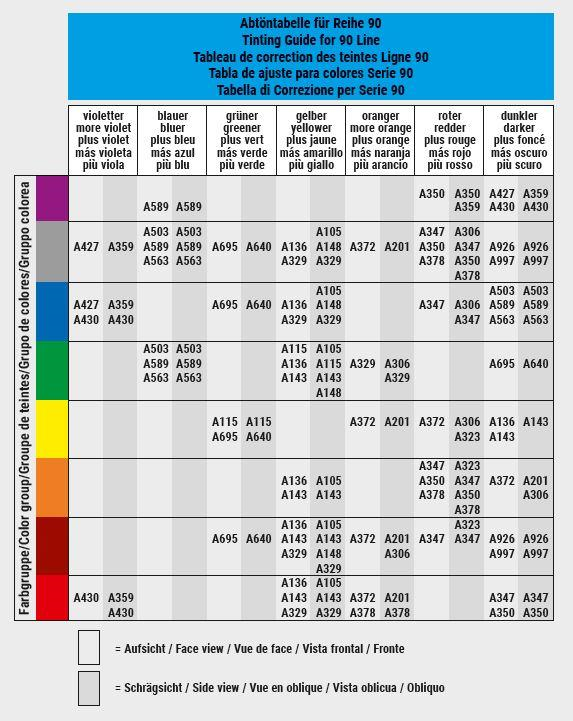

TINTING GUIDE

The guide provides a matrix showing the mixing base to be used to adjust the color for a certain color group.

PLEASE NOTE: In the first step, try to match the color with the mixing bases from the mixing formula (This avoids the risk of creating metamerism). If you cannot match the color with these mixing bases, consult the color adjustment chart to select another mixing base.

PLEASE NOTE: In the first step, try to match the color with the mixing bases from the mixing formula (This avoids the risk of creating metamerism). If you cannot match the color with these mixing bases, consult the color adjustment chart to select another mixing base.

SPECTROPHOTOMETER

The spectrophotometer provides two main benefits for color adjustment:

- Its measurement of the color provides you with the best-suited starting point for the color adjustment. The additional benefit of using a spectrophotometer is that the remission curves can be checked and considered for color adjustment accordingly. The color pigments used in the color are identified and the risk of metamerism is eliminated (COLOR RETRIEVAL WITH RATIO SCAN II and COLOR RETRIEVAL WITH RATIO SCAN 12/6)

- The ICCM software provides the possibility to perform color adjustment using an algorithm.

DEFINING THE STARTING POINT

In the automotive refinish business you can usually identify the starting point using a common color retrieval process.

“COLOR RETRIEVAL WITH RATIO SCAN II”

“COLOR RETRIEVAL WITH RATIO SCAN 12/6”

“COLOR RETRIEVAL WITH COLOR PROFI SYSTEM (CPS)”

In addition to the difference in color, please consider the criteria below:

- No metamerism

- Similar color drift under different light conditions

- Parallel remission curves (only with spectro)

- Same manufacturer (if 90 Line, 55 Line or 22 Line is used, due to metallic pigment size)

- In the case of effect colors, comparable effect pigments

- Equal texture, sparkle of the effect pigment

- Similar flip behavior of the color

- Same manufacturer (if 90 Line, 55 Line or 22 Line is used, due to metallic pigment size)

ADJUSTING SOLID COLORS

In general, three dimensions constitute factors for color adjustment:

- Chroma

- Purity

- Brightness /PROCESSES/COLOR-PHYSICS

When you add a mixing base to a color, you also adjust the brightness, purity and chroma of the color. You move the color in the direction of the mixing base for all three dimensions.

White mixing bases

Generally increase the lightness of a color and, at the same time, its purity. White mixing bases from one paintline may have slight differences in color bias, different tinting strength and opacity. Accordingly, the different white mixing bases give rise to different tinting behaviors.

If you add a white mixing base to a high-chroma red, the color will lose purity and become milky or even pink. To keep the high chroma of a pure red and make it brighter, you have to select a pure bright red or orange mixing base.

Black mixing bases

Reduce colors’ purity. Different blacks from one paintline may have slight differences in color bias (purity of the color, brilliance or chroma), tinting strength and opacity.

Colored mixing bases

provide pure and some transparent colors and are accordingly placed in the outer part of the color circle. They affect the color by keeping or increasing the purity of a color and they adjust the color’s chroma. Choose a mixing base in the direction of or adjacent to the target color (e.g., to make a green color bluer, add bluish green or blue mixing base). If you use a mixing base on the opposite side of the color circle, you will lose chroma and the color’s purity.

There are, however, also some colored mixing bases with less purity. These mixing bases are placed more toward the center of the color circle.

Before starting the color adjustment, get a clear picture of how the color has to be adjusted.

- Does the chroma need to be adjusted and if so, in which direction (blue colors in the direction of red or green, yellow in the direction of red or green, red in the direction of blue or yellow)?

- Does the color need to be purer or dirtier?

- Does the color need to be lighter or darker?

With this in mind, select the mixing base or the combination of mixing bases to adjust the color toward the target color.

Good tools for this are the color adjustment chart and in particular, the color circle showing the position of the mixing bases within the color circle. Try to place your current color and your target color into this color circle and you can easily identify the mixing bases that move the color in the targeted direction.

PLEASE NOTE: Pay attention to the concentration of the mixing base! In the first step, try to match the color with the mixing bases from the mixing formula. (This avoids the risk of creating metamerism.) If you cannot match the color with these mixing bases, consult the color adjustment chart to select another mixing base.

PLEASE NOTE: Pay attention to the concentration of the mixing base! In the first step, try to match the color with the mixing bases from the mixing formula. (This avoids the risk of creating metamerism.) If you cannot match the color with these mixing bases, consult the color adjustment chart to select another mixing base.

ADJUSTING METALLIC COLORS

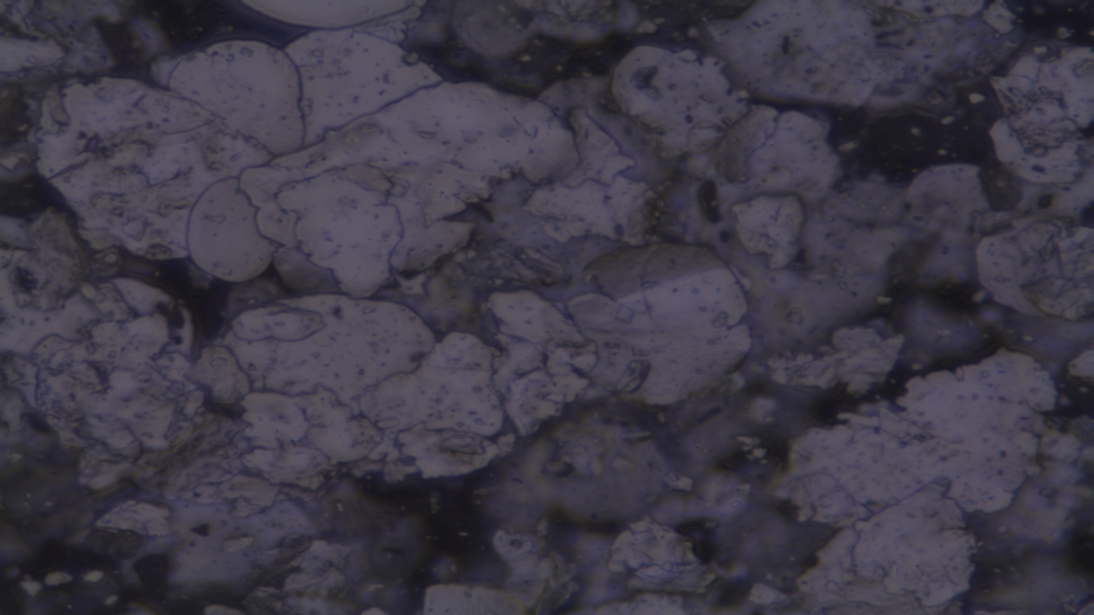

Metallic pigments are produced from crushed aluminum. They are dispersed in the paint as flakes ranging from 10 µm to 55 µm.

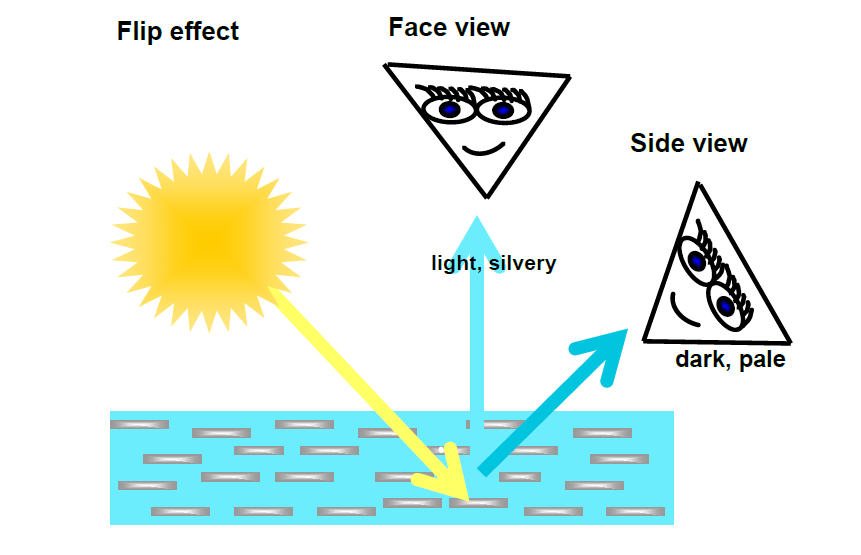

The main effect of these metallic flakes in the paint is that the light is mainly reflected on their surface and not homogenously scattered. Thus, the color appears brighter in the reflection angle (face view) and darker in the shadow zones (side view). This effect is referred to as the “flip effect”.

Viewing angle (flip/flop effect): 1) Light 2) Face view 3) Side view

This module offers further information on the viewing angle BASIC KNOWLEDGE COLOR: VIEWING ANGLE

The flip effect is brought about by the aluminum pigment. There are different sizes, size distributions and different types of aluminum pigments with different flip behaviors.

There are two main families of aluminum pigments:

|

CORNFLAKES (E.G. 100-M 95 OR 90-M99/03) Character: frazzled, high and low segments (front and back flat) |

SILVER DOLLARS (E.G. 100-M 992 OR 90-M99/01) Character: looks like a rolled coin, very homogenous, plain surface, more directed light reflection (front and back lighter) |

|

"Cornflake” aluminum pigment type |

"Silver dollar” aluminum pigment type |

Beside the three above-mentioned dimensions for color adjustments for metallic colors, two additional factors must be taken into consideration:

- Brightness

- Purity

- Chroma

- Texture of the color

- Flip effect

Adding a mixing base to a color allows you to adjust all five dimensions simultaneously.

White mixing bases:

Generally provide opaque pigments that hide the aluminum flakes in the paint layer and accordingly reduce the sparkle effect and the flip effect as well. Adding white mixing bases to a metallic color reduces its sparkle, makes it milkier in the front view, and lighter and milkier in the side view. When it comes to metallic colors, white mixing bases are not suitable for increasing brightness. To do this, you must use an aluminum mixing base.

Figure: Opaque pigments (dark particles) partially hide the surface of the aluminium flakes.

Aluminum mixing bases

Increase the brightness of a color. At the same time, they reduce the purity of the color. Furthermore, aluminum bases define the texture (coarse/fine) of the color and the flip effect. The flip effect is controlled by the type of pigment. Cornflakes provide less flip effect and sparkle in comparison to silver dollars. Finer aluminum types provide less flip effect compared to coarser aluminum types.

Pitch/effect controllers

(Glasurit 100-M 1, 90-M 1 or 55-M 1) adjust the flip effect and the texture. In general adding or increasing the amount reduces sparkle and the flip effect. The color and the effect can change in the front view and side view. At the same time, the texture of the color becomes coarser.

Black mixing bases

reducing color purity. Different blacks from one paintline may have slight differences in color bias (deepness), tinting strength and opacity.

Colored mixing bases

generally provide pure and transparent colors and are accordingly placed in the outer area of the color circle. They affect the color by preserving or increasing the purity of a color and they also adjust the chroma of the color. To evaluate the chroma, focus priority to considering the side view, because you will receive a better impression of the color. For the front view, the eye is irritated by the bright reflected light from the aluminum flakes, especially for bright colors.

Choose a mixing base in the direction of or adjacent to the color of the target color (e.g., to make a green bluer, add bluish green or blue mixing base). If you use a mixing base on the opposite side of the color circle, you will lose chroma and purity of the color.

In addition, when selecting the mixing bases, you must consider their effect for the front and the side view. The pictograms and tinting guide tables in the color adjustment charts also provide you with clear indications of the tinting behavior of the individual mixing bases. Be sure to also consider the effect for the face view and for the side view.

Please see TINTING CHARACTERISTIC OF THE MIXING BASES of this module for more information.

Pictogram from the color adjustment chart, incl. explanation

Some color mixing bases have less transparency and more opacity. For these more opaque pigments, the effect is similar to that of white mixing bases. They reduce the sparkle effect for the front view and the side view becomes brighter.

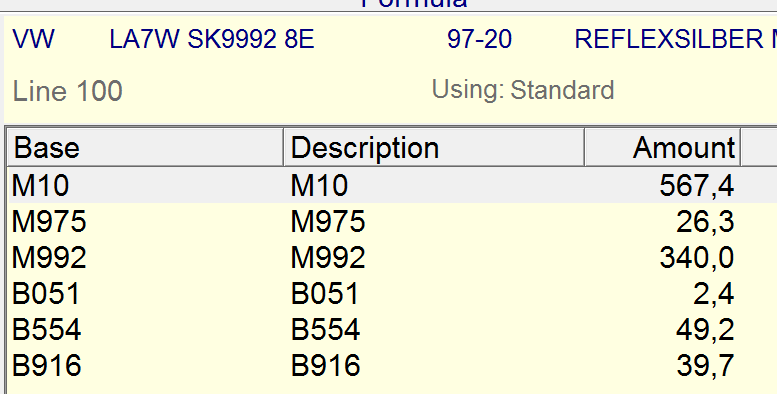

Mixing formula of VW LA7W

- If VW LA7W is used and the color has to be lighter, the amount of the aluminum types has to be increased in the same proportion.

- If VW LA7W is used and the color has to be darker, the amount of the aluminum types has to be lower in the same proportion.

- The effect is controlled by the proportion of 90- M1 in the mixing formula.

- If the color must be coarser, the quantity of 100-M 975, 90- M99/02 must be increased.

- If the color must be finer, the quantity of 100-M 992, 90- M99/01 must be increased.

If the proportion of the mixing bases is increased by up to 10%, the 90-M4 share does not need to be adjusted. If you have to add more than 10% mixing base, you have to adjust the amount of 90-M4. If 100 Line mixing base is added, add the same amount of the Mixing clear, which is already used in that formula.

PLEASE NOTE: Pay attention to the concentration of the mixing base! In the first step, try to match the color with the mixing bases from the mixing formula. (This avoids the risk of creating metamerism.) If you cannot match the color with these mixing bases, consult the color adjustment chart to select another mixing base.

PLEASE NOTE: Pay attention to the concentration of the mixing base! In the first step, try to match the color with the mixing bases from the mixing formula. (This avoids the risk of creating metamerism.) If you cannot match the color with these mixing bases, consult the color adjustment chart to select another mixing base.

ADJUSTING PEARL EFFECT COLORS

In addition to the aluminum pigments, other effect pigments are available. These effect pigments are made of flakes that have a core. The core of the effect pigments can consist of different materials:

- mineral, transparent mica

- synthetic, transparent material

- aluminum flakes

|

ALUMINUM OXIDE (E.G. 100-E 517 OR 90- E520) |

MICA (E.G. 100-E 516 OR 90-M505) |

|

Character: Symmetrical form, Surface has same color |

Character: Non symmetrical form, transparent, different color shades |

The surfaces of these cores are treated with metal oxide. The combination of core material, metal oxide and the film build of the metal oxide creates the final effect and color of the pearl effect pigment.

The pearl effect pigments reflect or partly reflect the light the way aluminium flakes do and provide a flip effect. The pearl effect pigments have visible flakes and, like the aluminum flakes, add a texture (fine/coarse) to the color.

In addition, the pearl effect pigments provide a color or at certain viewing angles.

The tinting behavior of white, black, pitch/effect controller and colored pigments is as described for the metallic colors.

Pearl effect mixing bases increase brightness for the face and side views. Furthermore, the addition increases the sparkle effect. They could also increase purity and color.

COLOR ADJUSTMENT TECHNIQUES

BELOW ARE SOME GUIDELINES FOR THE COLOR ADJUSTMENT PROCESS:

Percentage increase

When adding mixing bases, it is advisable to reduce and increase mixing bases in relative (percentage) steps.

Maintenance of mixing machine and mixing bases

To achieve reliable and reproducible results, be sure to perform maintenance of the mixing bases and mixing machine.

Color mixing

To achieve reliable and reproducible results, be sure to work accurately during color mixing. If you add more than 10% mixing base, be sure to restore the mixing base and mixing clear to the correct balance. If you add 100 Line tinting bases, add the same amount of mixing clear. For ready-for-use mixture, also take reducer and hardener into consideration.

Spray-outs (application technique)

Apply spray-out samples for each tinting step. Ensure that you maintain the standards of regular application during repair.

Color evaluation

Evaluate the color under appropriate daylight conditions and by using different light types to check for metamerism.

Documentation

For the tinting steps, note the preferred mixing formula on the reverse side of your spray-out card.

/PROCESSES/BASIC-KNOWLEDGE-COLOR

/PROCESSES/COLOR-AND-PAINT-PREPARATION